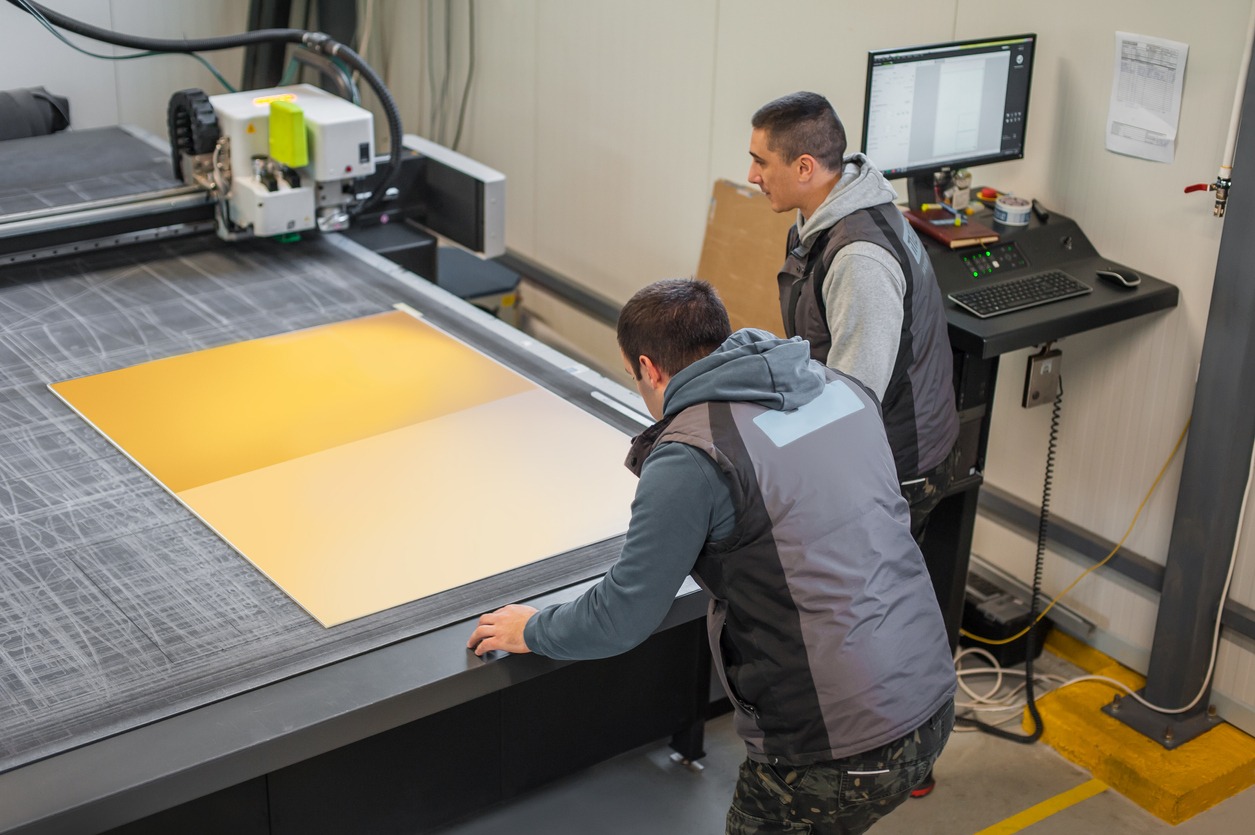

Woodwork, carpentry, modern mason work, and a host of other names aren’t everyone’s cup of tea especially when they don’t have the right told for the job. However, since the turn of the decade, there has been a plethora of superb apparatus that makes the whole thing quite easy and awesome. One of that specialized equipment is the computer numerical control (CNC) better known around the industry as CNC router, a tool which is used for helping in the cutting of materials like steel, wood, aluminum, composites, plastic, and foam. This tool is special as it comes with the ability to use computer numerical control to route tool paths that enable the machine to function. They are also kind of a big deal as they reduce waste and increase productivity, producing various items in a much shorter amount of time than a couple of other machines that purport to serve similar purposes.

So, what is a CNC router used for? CNC routers might be some of the best inventions in the field of woodwork, but they still have some way to go before they become as popular as some of their “peers” in the industry, and that’s why we’re here. We’ll be taking you through the nitty-gritty of CNC routers, showing you the importance of having one in your woodworking shop, discussing the tabletop types, the pros, the cons, and at the end we’re pretty sure you’ll have a deeper understanding of this super essential equipment for woodworkers around the globe. So without further ado, let’s get to “routing”.

The Importance

As a result of its current state of not so much popularity, CNC routers aren’t getting the love they deserve. These routers are some of the most useful, if not the most useful in the whole industry, and we’ll be delving into the importance in a bit. But before we do that, it would be necessary for us to tell you about the size of a typical CNC router, so you’ll know how to plan along to that effect. CNC routers aren’t child’s play, as the older versions are quite large and are known to take up large chunks of space, so you should put that in your planning before you make an order for your machine.

However, due to demand and the radical shift in technology, there are a lot of CNC routers that are space-conscious and can fit into workplaces without causing any issues. We advise that you get that sort of CNC router, except you’re into huge woodwork projects and can’t avoid getting the bigger versions.

So what’s the importance of these CNC routers anyway?

1. They’re Great for Manipulating Wood

Woodwork is no easy feat, especially when you’re looking for a final product that would wow onlookers and takes your brand to the next level. In this social media stage, it’s super important to get picture-perfect woodworks done, and what better tool to get that done than the CNC routers? All you need to do is to learn how to operate the CAD and CAM software on your laptop or smartphone, then you’ll tell the CNC router exactly how to cut the wood at precise angles, and you’ll get your results. There you have it, wasn’t that easy?

2. Precision

Human beings might be some of the most intelligent creatures on the planet, but it’s not wholly inaccurate to say that they don’t even come close to some of the machines in circulation these days. That’s the case when looking for precision in woodwork, no matter how good the handyman is at math, it’s next to impossible for such a person to get the exact measurement or precision in the task that he or she desires. That’s why it’s a pretty smart idea to leave that task for the CNC router. Thanks to the already stored measurements in the router, and the top-notch technology behind it, it’s fair to say that your job has been made radically easier.

3. Versatility

Versatility is the second most important thing in woodwork, as the handyman cannot know the next top gig he’ll get, that’s why they’re always advised to master as many skills as possible. That must be the reason why the inventors of the CNC router went to work, as this apparatus exudes versatility in its truest form. CNC routers are reputed to be able to cut up to thirty different materials from wood to steel, foam, plastic, acrylic, and more. So what exactly are you waiting for? Your work has been radically improved, you can focus on some other pressing needs, and the best part is that CNC routers are super safe and the manufacturers took their time to assure security for the purchasers.

Table Top Types

There’s a saying that goes “different strokes for different folks”, but in this context, we’ll be using the paraphrase “different table tops for different CNC routers”. These days, tables are super important for CNC routers, as most CNC routers are smaller when compared to the older versions, and they’ll need a comfortable table to be nestled on. That’s why we’ll be running through the table types here, and hopefully, it’ll help your decision when getting your very own CNC router.

1. Disposable Table Top

These are table tops that don’t have the lifespans of the others in the game, but they certainly have their advantages. One advantage is that they are quite cheap, and super affordable compared to the rest of their kind. They are also pretty durable if you get them from a good source, and they’ll last for a while as long as you take an excess load off it once the load isn’t in use. A disposable tabletop is pretty advisable for a handyman that isn’t into the woodwork as the main job, as it’ll be tomfoolery to purchase a different kind of table for a lot of money and end up barely using it.

2. Perforated Table Top

These tabletops are pretty useful for router tables, especially for the ultramodern and super loved CNC routers. They are an asset to handymen that can afford them, thanks to the breathability they assure. Perforated tops typically have a few holes which are necessary for a lot of machines and equipment to operate normally, as with this you’ll be sure that the CNC router would work in all clear terms. Another bonus is that perforated tops are some of the most stylish around.

3. Vacuum Table Top

While this is the most expensive of the lot, there’s no doubting that it lives up to the price tag and doesn’t disappoint the lofty expectations. Vacuum tops tick a lot of boxes, as they can be divided into four, six, or eight zones. Hence, the adsorption function would be enhanced in a way hard to imagine in other tabletops or what have you. Also, this tabletop is super firm, and you’ll spend your time doing other things instead of painstakingly trying to make sure that it doesn’t shift or ruin measurements.

Like we said at the beginning of this piece, “different strokes for different folks”, so a tabletop that might be amazing for you, might not be a cup of tea for your next-door neighbor. It’s all about weighing the pros and cons and speaking of pros and cons.

Pros and Cons of using a CNC Router

CNC routers might be super innovative, and almost certainly a breath of fresh air, compared to the days when handymen painstakingly had to do all these things manually, but they aren’t exactly perfect. So in line with tradition, we’ll be showing you some of the merits of this generational woodwork tool, while we’ll be itemizing some of the not-so-cool aspects of it. Let’s get to it, shall we?

Pros

1. Versatility

Your typical CNC router is super versatile, and it ticks that box quite finely. It can be used to process a wide range of materials on the table of your choice. Everything ranging from soft & hardwoods like pine, walnut, oak as well as MDF and plywood, OSB board right up to acrylics & plastics like Plexiglass and HDPE can be sorted with relative ease.

2. Options

Unlike in a situation where you’ll be doing this with your bare hands, CNC routers go the extra mile, as here you can easily produce different types of cuts such as drilling, pocketing, simple engraving with the simple pushing of a button.

3. It shortens the production time

CNC routers radically shorten the production time of the woodwork product being handled. Now you can do more in lesser time without compromising on quality.

Cons

1. The Noise Factor

Just like in most other tools that perform similar functions, CNC routers are pretty noisy, and they could be borderline annoying if you’re using them in a residential environment. It’s no surprise due to loads of work being done, but that doesn’t make it any less annoying.

2. The Unemployment Factor

While we can’t deny that CNC routers help the work go faster, and they’re radically more accurate than humans. It’s no secret that a lot of capable hands have lost their means of livelihood because of sophisticated technology like this taking away the only jobs they know how to do. That seems like a painful pill to swallow for a lot of good handymen.

Final Thoughts

Technology is the best way forward in woodworking, and only a few technological inventions do the job like CNC routers. CNC routers tick so many boxes, and even though they have a few flaws, it’s no surprise that a lot of handymen have purchased theirs and learned the nooks and crannies of the operation. No one wants to be left behind, and this is especially through when the machine is as versatile as this.

There are so many kinds of CNC routers on the market, so it all boils down to your preference. Whether it’s a smart decision to invest in such a machine, that’s already a foregone conclusion right about now!