The Industrial Revolution, which started in Great Britain in the mid-18th to early 19th century and then went global, was all about big advancements in machinery and creativity. The Brits initiated this by using coal and iron. Meanwhile, over in the USA, the Second Industrial Revolution, kicking off in the 1870s and lasting until World War II, focused on automating farming and manufacturing, plus introducing cool new ways to get around, like steamships, cars, and airplanes.

The Industrial Revolution brought about a change from agricultural-based economies to manufacturing-driven ones. Instead of relying solely on manual labor, machines started doing the heavy lifting, resulting in higher production rates, improved efficiency, lower costs, a wider variety of products, better pay, and a shift of people from the countryside to bustling cities.

How It Happened

Around the early 1800s, Richard Trevithick unveiled a steam-powered train, and by 1830, similar locomotives were moving cargo (and people) between Manchester and Liverpool, two industrial hotspots. Meanwhile, steamboats and ships were already well-established, ferrying goods along British waterways and even across the Atlantic.

Although people in Britain had been gradually migrating from the countryside to cities before the Industrial Revolution, this urbanization process went into overdrive during the industrialization phase. Large factories popped up, transforming small towns into bustling cities in just a few decades.

Changed The World Forever

The Industrial Revolution was a period of significant change that transformed society from predominantly agrarian (based on farming) to industrial and urban. Several key technologies played a crucial role in driving this transformation:

Steam Engine: The steam engine was one of the most revolutionary inventions of the time and was the driving force behind the whole Industrial Revolution. It allowed machines to do work previously done by humans or animals. Steam engines powered trains, ships, and factories. This made transportation and production much more efficient.

Spinning Jenny and Power Loom: These inventions revolutionized the textile industry. The Spinning Jenny allowed one worker to spin multiple threads at once, while the Power Loom automated the weaving process. This greatly increased the speed and efficiency of textile production.

Water Frame: This was another textile innovation. It used water power to drive spinning machines, further increasing the output of textiles. Water-powered mills became common during this period.

Iron and Steel Production: Advances in iron and steel production techniques, like the Bessemer process, led to the mass production of strong and durable materials. This was crucial for building machines, railways, and bridges. Communities were connected faster and buildings were built stronger with this advancement in metallurgy. Many of the structures made during this era still stand today.

Railways: The development of railways enabled faster and more reliable transportation of goods and people. Commerce immensely benefited from this development. This also facilitated the migration that followed the industrialization of many cities at the time. This made it easier to move raw materials to factories and finished products to markets.

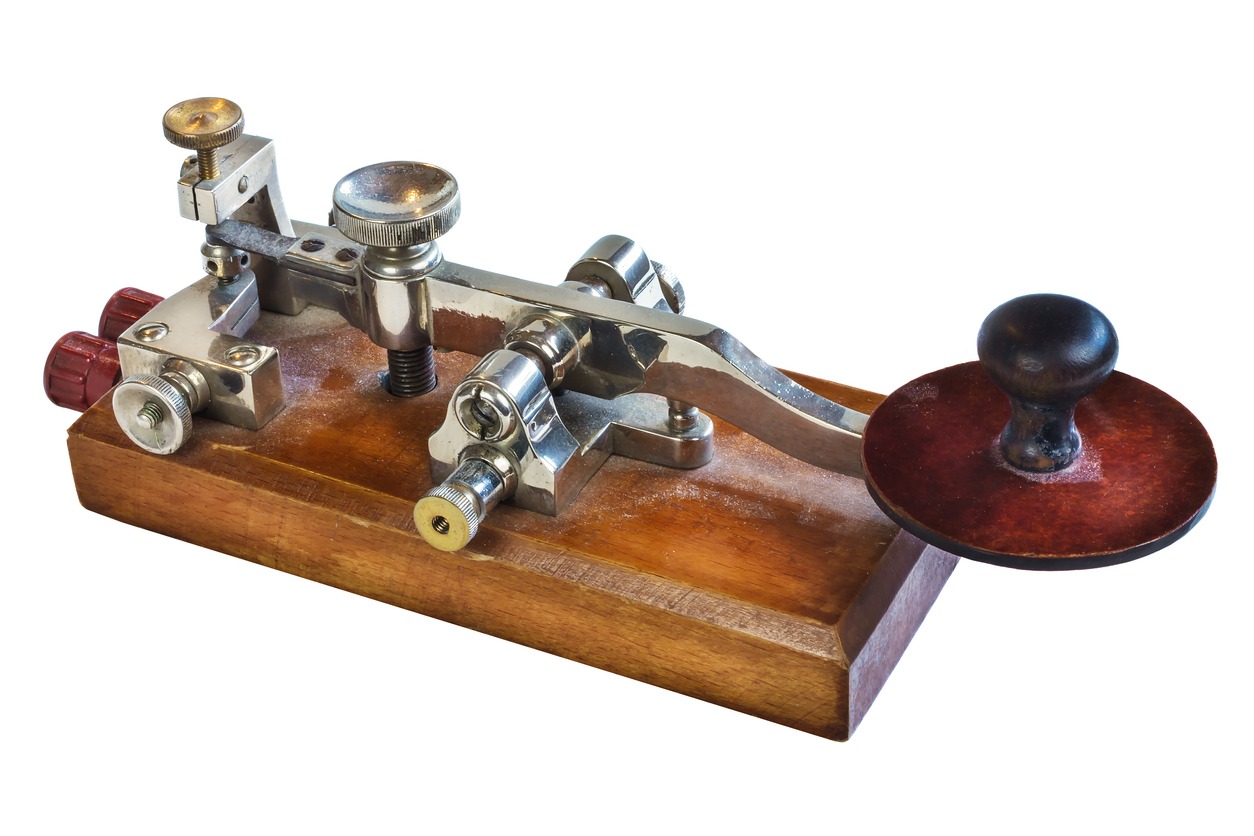

Telegraph: The telegraph allowed for long-distance communication using electrical signals. It improved coordination in industries and made it possible to transmit information quickly across great distances. This tech changed the way the following war was fought. Messages that used to take days to deliver was now accessible in record speed.

Coal and Steam Power: The widespread use of coal as a fuel source, especially for steam engines, provided the energy needed to power factories, ships, and trains. Steam power was initially used to draw water out of coal mines but it eventually became useful for many other operations as well, making it the literal “fuel” to the innovations of the time.

Mechanical Looms: These automated the weaving process, making cloth production much faster and more consistent. It reduced the reliance on skilled labor for weaving.

Interchangeable Parts: This concept allowed for the mass production of standardized parts that could be easily replaced, leading to more efficient and cost-effective manufacturing processes. Nuts and bolts or machines were made in standard size graduations making it easier to assemble and repair units necessary in the production lines.

Factories: The development of factories brought together large numbers of workers and machines under one roof. This concentration of resources and labor allowed for greater production and efficiency. Human resource shifted from skilled labor to machine operation.

Building Cities

This era totally shifted the way folks lived and how businesses were run. You could even say that the factory systems developed during the Industrial Revolution played a big role in shaping capitalism and the cities we have today, as well as the lifestyle shift that came along with it.

Before this time, most families earned their keep by farming and lived mainly in smaller rural villages. But when factories emerged in the 18th century, people started working for companies in cities for the very first time.

The Industrial Revolution saw a boost in production efficiency thanks to innovations like the steam engine. This invention drastically sped up the manufacturing process, leading to lower product prices, mainly because labor costs dropped. This, in turn, made products more accessible to a wider range of customers.

It also generated more job openings. With the spread of factories, there was a need for more managers and workers to run them, which increased the number of available jobs and wages.

Because factories and big companies were mainly situated near cities, people flocked to urban areas in search of work. This often strained the housing resources, pushing for better city planning. The boost in innovation also brought about better education as more children were close enough to attend urban schools, resulting in several game-changing inventions still in use today, like using X-ray, lightbulbs, calculators, and even anesthesia.

The simplicity of most tasks allowed for unskilled workers, even children in some cases, to toil for extended hours, alongside a machine that would do most of the work. And for this, most of the lower working class earned meager wages, just enough to make it through a few days of city living.

Conclusion

Historians continue to discuss various aspects of industrialization and the idea that it may have been more of a gradual evolution than a sudden revolution. The pros and cons of the Industrial Revolution are intricate and often depends on the narrator.

On one hand, there were widespread unsafe working conditions and long-term environmental issues like coal and gas pollution that accumulated and still affect us today. On the other hand, the migration to cities and clever inventions that made clothing, communication, and transportation more affordable and accessible to the masses reshaped world history as we know it.

Despite these debates, the Industrial Revolution undeniably had a profound impact on the economy – not just of Britain and the United States, but of the rest of us where these innovations eventually trickled down to. Commerce, society, and culture evolved with it and it played a pivotal role in setting the stage for the modern world.